Hay Tool Parts Checklist: Keep Your Equipment Running Smoothly

“Hay” there!

The weather’s gotten a lot better! Don’t let a dull blade, a missing part, or a sudden breakdown make a supposedly smooth hay season chaotic.

What seems to be minor setbacks can escalate into major problems (and a lot of downtime) if not checked regularly. Don’t let a preventable issue cost you precious hay-making hours.

Here at RangeLine Group, we understand the importance of equipment maintenance. So, we put together this quick checklist to keep your farm operations running smoothly. READ MORE!

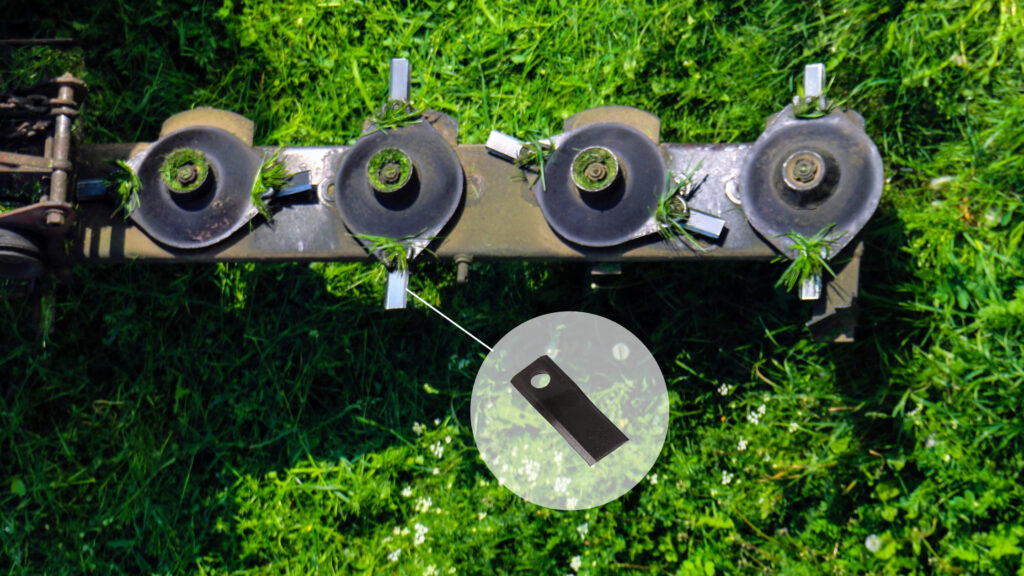

Imagine running your equipment over a thick patch of hay with dull disc mower blades. The result? Uneven cuts, ragged edges, and a strained engine working overtime.

Here’s the key: regularly sharpened blades make clean, precise cuts on your hay, reducing stress on your mower and ensuring a smooth, efficient operation.

Keep the Power Flowing: Driveline Parts

The engine is the heart of your farm equipment, pumping out the fuel. But that fuel needs a smooth path to reach the working parts, like the mower blades or the tedder.

That’s where the driveline comes in – belts, clutches, and U-joints working together behind the scenes to deliver power from the engine to the tools.

The problem? Worn driveline parts are like a twist in a garden hose – the power (water) just doesn’t flow as well. This means your equipment works harder, becomes less efficient, and can even slow you down.

Avoid a mid-field stall by regularly inspecting your driveline parts. Catch worn components early and replace them before they cause a major slowdown.

Bearing the Load: Unsung hero

Inside every huge farm equipment are tiny parts moving in perfect harmony, working tirelessly, to keep your farm operation smooth: the bearings.

These remarkable components handle immense pressure, allowing all the other parts to rotate smoothly with minimal friction.

Worn bearings become noisy, create excessive friction, and generate heat. This not only reduces efficiency but can also lead to a complete breakdown, bringing your entire haying operation to a halt.

By keeping your bearings in top shape, you ensure a smooth, efficient, and trouble-free haymaking.

Pickup Teeth: Pick every piece

Imagine trying to load a wagon with hay using a bent fork and a number of missing pieces. It will most likely be impossible to grab a good hold.

That’s exactly what happens to your hay equipment when pickup teeth are missing or broken.

Regularly inspect your pickup teeth for signs of wear and tear, such as missing pieces, bends, or excessive dulling. By replacing worn teeth promptly, you ensure your equipment gathers every last bit of hay.

Maintaining Edge: Sharp Tedder & Rake Tines

These sharp components are responsible for a crucial step in the haymaking process: fluffing and turning the hay to ensure even and efficient drying.

But worn-out tedder teeth simply can’t do their job effectively, leaving you with unevenly dried hay and potentially wasted time waiting for proper moisture levels.

Don’t let your hay turn into a lumpy mess! By replacing your tedder and rake teeth promptly, you ensure your hay gets the proper “fluffing” it needs to dry evenly and quickly, maximizing your harvest potential and keeping your operation on schedule.

When to Replace Hay Tool Parts

There’s no ideal time for replacing hay tool parts. It depends on how you use your equipment (heavy duty vs. light work) and the conditions it tackles. Wetness and dryness matters, so if the hay is too tough and has too much moisture, it’s a good idea to make sure of the correct moisture level before baling.

If the hay is too wet when you bale, you could end up with moldy bales, which would then become unusable for livestock.

But here’s the good news: you can spot wear and tear before it becomes a major problem. Here’s what to watch for.

Spot the Damage:

Look for cracks, broken bits, or parts that seem worn down.

Hear the Warning:

Unusual noises coming from your hay tool can signal trouble.

Feel the Difference:

If your hay tool isn’t performing as smoothly as usual, it might be time for replacements.

By catching these signs early and replacing worn parts, you can avoid surprise breakdowns and keep your haymaking season running like clockwork.

Where to find quality hay tool parts?

At RangeLine Group, we stock thousands of hay tool parts for all your equipment needs.

Whether it’s disc mower blades, bearings, or that specific tedder tine you’ve been searching for, we’ve got you covered.

Plus, with our extensive inventory and focus on fast shipping, you can bulk-order the parts you need with confidence, knowing they’ll arrive on schedule.

Skip the hassle and head over to www.rangelinegroup.com to find the parts you need for your hay equipment!